Ethylene Bis Stearamide(EBS) CAS:110-30-5

Name: Ethylene Bis Stearamide(EBS)

CAS: 110-30-5

Feature:

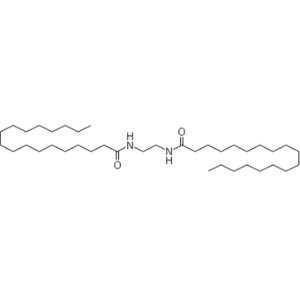

Ethylene Bis Stearamide(EBS) is an organic compound with the formula (CH2NHC(O)C17H35)2. It is a waxy white solid and is also found as powder or beads that is widely used as a form release agent. Ethylene Bis Stearamide(EBS) is a synthetic wax made by combining two stearic acid molecules with one molecule of ethylenediamine. The compound is derived from the reaction of ethylenediamine and stearic acid. Ethylene Bis Stearamide(EBS) is non-toxic, has no smell and is not soluble in water at room temperature. It has solubility in chlorinated or aromatic solvents. Ethylene Bis Stearamide(EBS) is harmless to human body and living body, so it can also be used as food packaging material, auxiliary agent, additive and so on.

Ethylene Bis Stearamide(EBS) is one of the earliest developed fatty bis-amide products. The structure of Ethylene Bis Stearamide(EBS) contains polar amide group and two hydrophobic groups with long carbon chain, which makes it have the characteristics of high temperature lubricity and low temperature anti-sticking. In addition, it has good compatibility with synthetic resins such as acrylonitrile-butadiene-styrene polymer (ABS), polyvinyl chloride, phenolic resin, polystyrene, etc.

Ethylene Bis Stearamide(EBS) has the following applications/functions:

1. The primary use for Ethylene Bis Stearamide(EBS) is as a release agent for PVC (poly-vinyl chloride) extrusion. It acts as both an internal and external lubricant to enhance malleability of the PVC resin. It will inherently lower the viscosity of the polymer resin and can decrease friction and abrasion of the polymer surface.

2. Ethylene Bis Stearamide(EBS) is also a dispersal agent and helps contribute to color uniformity and stability of the resulting extruded PVC product. Adding EBS to your thermoforming process will increase productivity by reducing shear stress. The overall product has a high gloss finish, smooth surface and increased tensile strength.

3. It is also used in process industries as release agent and antistatic agent for the production of thermoplastics,and wiring. It is used in powder metallurgy.

Composition:

Appearance: White powder

Packing: 25kg/drum or as discussed

Shelf Life: 2 years

Storage: Store in cool and dry area

Certification:ISO GMP KOSHER HALAL

![Benzyl N-[2-(piperidin-4-yl)propan-2-yl]carbamate hydrochloride CAS:1057260-89-5](https://cdnus.globalso.com/puyerinternationalgroup/2611-300x300.jpg)